download Nanjing Swansoft CNC Simulator 7.1.2 32bit 64bit full crack 100%

Download cnc simulator windows 10 for free. Photo & Graphics tools downloads - CNC-SIMULATOR by BULLDOG DIGITAL TECHNOLOGIES and many more programs are available for instant and free download. Complete package that includes: a) machine simulation teaches the student the setup and operation of CNC machines. B) CNC program simulation and g-code debugger teaches programming. C) Server module allows the instructor to manage students and tests.

Link download SSCNC 7.1.2 full crack

Nanjing Swansoft CNC Simulator 7.1.2

Nanjing Swansoft CNC Simulator 7.1.2 full

download Nanjing Swansoft CNC Simulator 7.1.2

Nanjing Swansoft CNC Simulator 7.2.1

5 axis Nanjing Swansoft CNC Simulator 7.1.2

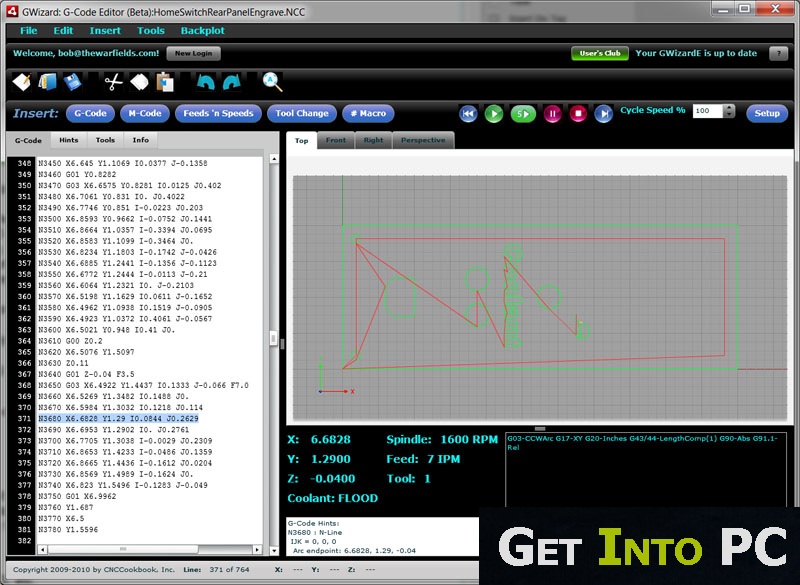

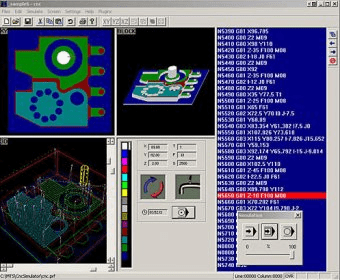

program SSCNC Simulator 7.1.2 includes milling and turning groups of machines CNC. program SSCNC Simulator is designed both for students and for experienced professionals in the field of setting and programming CNC machine tools. SSCNC Simulator program is used as the same in the production of G-code debugging and programming CNC machine tools “by hand”

Main Program Features

Full simulation of CNC machine set-up and operation.

Programming with G-code.

Parametric programming.

Error Identification and removal of G-code

module that allows you to manage and monitor the work of students in the classroom.

SSCNC Simulator supports turning and milling group of machines.

2D and 3D Simulation of

3D-modeling based on the OpenGL, allowing you to quickly and accurately create a 3D image.

Realistic consoles different models of CNC machine tool control.

The mapping tool paths.

Support for multiple monitors.

The simulation of all stages of the process: the choice of the workpiece, resetting the workpiece, the choice and measurement

instrument, . choose the correct operating mode of the machine control panel

simulation includes realistic components such as coolant,

sounds and chip forming machining.

Installing and fixing the workpiece. Configurable zero workers, tool offset and

the use of various fixtures.

The three-dimensional measurement of the workpiece after its machining.

Measurements of surface roughness, based on the parameters of the cutting tool.

Material Library. Ability to edit and insert new material.

A wide range of cutting tools and the ability to edit it.

Tower instruments lathe can be configured for 4, 8 or 12 stations

(anterior or posterior location).

Store tools milling machine can be

set up horizontally or vertically.

The ability to use virtual tools for tuning and zeroing the blank:

determinant angle (mechanical and electronic), samples, probe, etc.

record, edit and run MACROS.

The ability to record videos and save as AVI format.

creating and editing programs

Ability to create programs directly from the control panel machine.

Programs are easily created in ASCII format, in any text editor.

The possibility of editing (cut, copy, paste).

The numbering and renumbering rows.

on-screen prompts during programming.

Check canned cycles and syntax of the G-below code

(respectively, standards of different models of control systems) .

Advanced programming features

G-code parser. Supports ISO-1056.

The codes describing the motion of (G-code), the auxiliary code (M-code).

Debugging Tools G-code.

The ability to simulate the constant cycles and parameters.

The possibility of using polar coordinates in FANUC, SIEMENS systems.

Helical interpolation (G02 , G03).

Support for custom code and cycles in different CNC systems.

Simulating a file created by the automatic programming systems (UGS, Pro-E, Master CAM.)

machine control CNC

Set G54 workpiece zero workers, G55, G56, etc.

Sizing tools and setting their values in the tool table.

Working with electronic handwheel for setting up the machine.

the JOG modes, MDI, EDIT, SINGLE BLOCK, AUTOMATIC, DRY RUN, STOP CYCLE, CYCLE START, EMERGENCY , etc.

Adjusting the cooling system.

Signalling collision with the workpiece tool, vise, and other parts of the machine.

Adjustment of the machine parameters.

Perform all operator functions. This simplifies the learning process and provides the best adaptation of the

students to the CNC machines.

If you want to download this version of SSCNC 7.1.2 full, please click to DOWNLOAD symbol and complete check out a little help my website is maintained. The download link is appeared automatically when you complete check out.

Please see youtube video for download instruction by open *.txt file and copy youtube video link paste to your browser If you don’t know how to download.

Inside folder SSCNC 7.1.2 full, already have crack’s file and instruction how to install this version of SSCNC 7.1.2 full step by step. I guarantee you can install SSCNC 7.1.2 fullsuccessfully if you follow that instruction.

If you also can not install it or any problems, please contact to me by email: hades@clickdown.org , then I will help you to install software by teamviewer.

Thanks a lot

A handy machine simulator application that can definitely help you learn how to program and operate it using a comprehensive interface

What's new in Machining Simulation 2.1.5.5 Mill:

- Fix of radius compensation.

- Update milling cutter to round nose milling cutter.

Machining Simulation is an application especially designed to help you get familiar with what it takes to using a CNC machine.

A CNC, or a ‘Computer numerical control’ machine is a vertically controlled milling machine which runs using programmed commands that are stored in a memory device. This means that a CNC machine is capable of milling with much higher precision and at faster speeds opposed to a manual one.

The interface of Machining Simulation is divided into two main sections, a 3D machine view, and an operator panel view. The first offers you a representation of how the CNC machine looks and even allows you to hide it’s body so you have a better view of what happens inside.You are able to zoom in for a closer inspection and have a real-time demonstration of how everything works.

Machining Simulation is designed for those who actually need to use the CNC machine or to familiarize themselves with it. If for you are none of those and are not in the least familiar with it, then gazing in the control panel is only going to be another way to waste time. The application displays a user-friendly interface, but if you don't have the slightest clue of how to use it, then you should grab a manual.

In terms of controls, it offers you the exact layout and buttons that a real machine has. They have the same functions and of course, if something goes wrong, you get to redo it without any actual loss of material or hardware damage.

Since it’s a learning tool, you get to save the workpiece and use of later as well as import previous project that you need to complete or correct.

With the above to consider and much more to discover, you can’t really see what Machining Simulation can do without actually testing it.

Filed under

Machining Simulation was reviewed by Alexandru Chirila

- Windows XP Service Pack

Machining Simulation 2.1.5.5 Mill / 2.1.5.9 Lathe

add to watchlistsend us an updateDownload Cnc Simulator Full Crack Gratis

Download Cnc Simulator Full Crack Free

- runs on:

- Windows 10 32/64 bit

Windows 8 32/64 bit

Windows 7 32/64 bit

Windows Vista 32/64 bit

Windows XP 32/64 bit - file size:

- 9 MB

- filename:

- GSMachiningSetup.exe

- main category:

- Science / CAD

- developer:

- visit homepage

top alternatives FREE

Download Cnc Simulator Full Crack Free

top alternatives PAID